IHI Corporation today announced a breakthrough high-flux plastic magnet rotor prototype for ultra-high-speed motors for aircraft and automobiles. This achievement is the fruit of collaboration with Akita University and three Akita Prefecture-based companies that leveraged support from the Akita Industrial Technology Center. They are Miyakoshi Seiki Co., Ltd., Furuya Mold Co., Ltd., and Kobayashi Industry Co., Ltd.

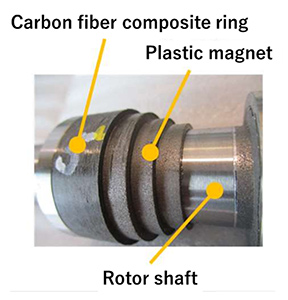

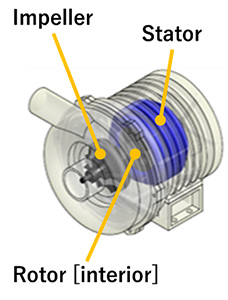

These magnet rotors, or motor rotors, result from injection molding molten plastic and powder magnet composites, orienting them in a magnetic field (see note 1) similar to that of a Halbach array (note 2) to maximize magnet utilization efficiency. high motor efficiency, compactness, and lightness. Injection molding greatly reduces machining, cutting manufacturing times and costs.

Covering the injected plastic magnets with a high-strength carbon fiber-reinforced polymer ring created a structure that can withstand motor speeds exceeding 100,000 revolutions per minute.

The Joint Research Center for Electric Architecture (note 3) assessed the finished prototype. It confirmed that the performance matched or bettered that of regular sintered magnet rotors in which magnets account for all of the designed magnetic force. delivering the same output with magnets that are almost 50% plastic.

IHI will keep developing electric hybrid propulsion systems for aircraft with a view to practical deployment in the 2030s.

Notes

- Magnetic field orientation refers to aligning crystals in materials by applying a magnetic field during magnet molding.

- A Halbach array is a special arrangement of permanent magnets. In a conventional magnet setup, both sides have the same magnetic force. A Halbach array augments the magnetic field on one side of the arrangement and reduces the field on the other side to almost zero, making it possible to maximize magnet usage efficiency.

- Akita University and Akita Prefectural University together run the Joint Research Center for Electric Architecture. That entity started out in April 2021 under a Cabinet Office project that draws its funding from the Subsidy for Regional University & Regional Industry Creation Project for Industry Creation.