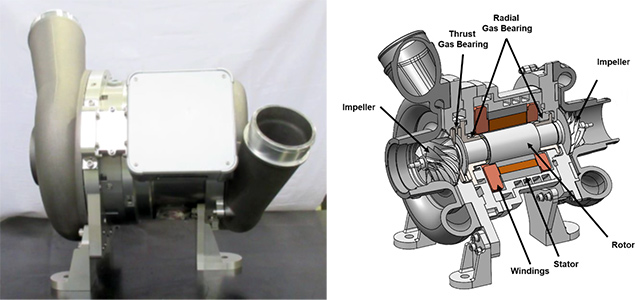

IHI Corporation announced today that it has developed an electric turbo compressor incorporating a proprietary air-floating gas-bearing electric motor (see note 1). With an output that is 3.5-fold that of the company’s predecessor model, this is one of the world’s most powerful and compact electric turbo compressors.

The company developed this compressor for the air conditioning units of new civil aircraft models, power generating systems for aircraft systems and electric hydrogen fuel cell aircraft. Combined with turbine blades that rotate using fuel cell steam discharges, the compressor can generate 100 kW of output. This would enable flight with a fuel cell propulsion system in the thin air of high altitudes.

IHI’s envisioned applications for this new compressor include fuel cell propulsion systems for small passenger aircraft, energy-efficient air conditioning in 200-seat medium-range airliners, and aircraft fuel cell systems, which could replace gas turbine generators to decarbonize aviation.

IHI developed this compressor as part of work on an electric hybrid system for R&D into a new-generation electric propulsion system, which the New Energy and Industrial Technology Development Organization commissioned in fiscal 2020 for a project to create practical applications for advanced aircraft systems.

As part of that work, IHI endeavoured to attain ultra-high speeds with a turbo compressor motor and meticulously lighten rotating parts. magnet rotor and high-powered impeller.

To achieve a compact, light, and powerful motor, IHI used a high-density magnetic array (see note 2) to maximize magnet utilization efficiency. Additionally, the company attained ultra-high speed rotation by developing a proprietary high-speed inverter technology to suppress heat generation during rotation. This inverter technology provides precise digital control at more than 70,000 times per second for the sinusoidal alternating current power of a 70kW motor. These technologies thus overcame issues with smaller diameter permanent magnets and heat generation that had been hard to resolve with conventional technology.

IHI will keep developing electric propulsion systems and hydrogen-fueled generators for aviation, with a view to commercializing them in the 2030s.

Notes

- This air-floating electric motor employs IHI technology (air (gas) bearings) to levitate a rotating body with an air layer generated around the motor during high-speed rotation.

- A high-density magnet array, or a Halbach array, is a special arrangement of permanent magnets. In a conventional magnet arrangement, both sides have the same magnetic force. A Halbach array augments the magnetic field on one side of the arrangement and reduces the field on the other side to almost zero, making it possible to maximize magnet utilization efficiency.